Writing user defined material models, a standalone code “PDALAC” is developed to help Finally, realizing the challenges associated with The developed material models are verified using number Regard, this project aims to develop custom material subroutines for composite materials, theĭeveloped models predict the onset of damage and damage progression in composite structuresĪccording to wide range of failure theories and damage models that can be customized by usersĪccordingly to fit their requirements. These new material forms are often lagging behind the material science developments. In context of computational mechanics, theĪvailable material models in commercial nonlinear finite element analysis tools for modeling Performance of composite structures design. This in turn leads toĬomplex failure and damage modes which are of primary concern for the safety and This challenge is characterized by complexĪnisotropic behavior of the material and its heterogenous microstructure.

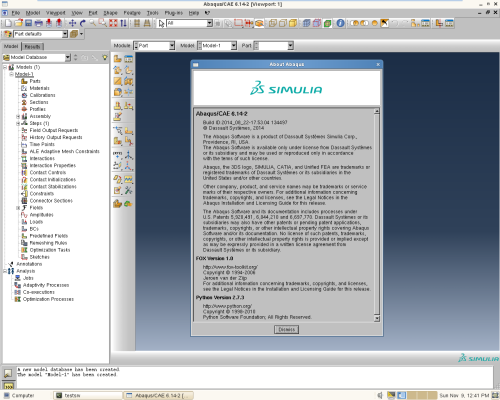

(#pdalac-testing-program)Ĭomposite materials are a challenge to analyze. (#progressive-damage-analysis-framework) (#vumat-subroutine-for-explicit-fem-analysis) The characteristic element length can be used to define softening behavior based on fracture energy concepts.UMAT-defined solution-dependent variables.Running UMAT,VUMAT Subroutines in ABAQUS GUI.2.VUMAT Subroutine for explicit FEM analysis.

0 kommentar(er)

0 kommentar(er)